Özelleştirmeler

ERP programı, özelleştirilebilen yapısı ile işletmelerin tam istedikleri sisteme dönüşebilmektedir. Tanımlanabilir kullanıcı arayüzleri, iş kuralları, raporları ve formları ile esnek bir platformdur. İşletmenin iş süreçlerine tam olarak uyum sağlayabilmek için gerekli her türlü teknolojik ve mimari altyapıya sahiptir. Sentez LiveERP, sadece gerekli olan bilgiyi içerecek şekilde düzenlenebilen kullanıcı arayüzleri ile, iş süreçleriniz gereği hazırlanan ek modülleri, ihtiyacınıza göre tanımlanabilen veri alanları ile, ihtiyaçlarınıza göre düzenlenmiş veya eklenmiş rapor ve formlar ile tam işletmenize göre uyarlanabilen bir çözümdür.

Parameterik Yapı

Sadece gerektiği kadar iş kuralı tanımlanır. Parametrik yapı sadeleştirilerek sadece gerekli olan işlemler bırakılabilmektedir. İş çözümlerinin esnekliği ve uyarlanabilirliği önemli ölçüde parametrik yapısı sayesinde gerçekleşir. İş süreçlerinin gereklerinin sağlanabilmesi için çok sayıda parametre ve varsayılan ön değer tanımlarına ihtiyaç duyulur. Hemen hemen sistemin her yerinde kullanılabilen bu parametrelerin karmaşaya yol açmadan, birbirlerini etkilemeden çalışabilmesi için mantıksal bir yapıda organize edilmiş olması gerekir. Sentez LiveERP, iş süreçlerinize uyum sağlayabilmek üzere gerekli olan çok sayıdaki parametre ve varsayılan değer mantıksal bir yapıda düzenlenmiş ve kurulum karmaşası en aza indirilmiştir bir çözümdür.

Geliştirilebilir Yapı

Sürekli bir değişimin içinde olan iş hayatı sistemin yeni şartlara ve yeni iş kurallarına ayak uydurmasını gerektirir. ERP programı, sistemin hiçbir zaman sona ermeyecek olan bu değişime göre tasarlanmıştır. İş yaşamının kaçınılmaz değişimlerine, gelişmelerine ayak uydurabilmek, bu amaçla tasarlanmış mimari gerektirir. Yükselen rekabet ortamında işletmelerin hızlı ve doğru karar verip uygulamaya geçmeleri gerekir. Alınan kararların başarıya ulaşabilmesi sistemin aynı doğrultuda uyarlanabilmesine bağlıdır. Özellikle ülkemizin şartları gereği rekabetçi, hızlı ve verimli olmamız bir zorunluluktur. Sentez LiveERP, sistem mimarisi bu bakış açısı ile hazırlanmış bir çözümdür.

Mobil Yapı

ERP programı, internet iş modellerini tamamen değiştirmekte, mobil iş yaşamı vazgeçilmez olmaktadır. Sentez LiveERP 7/24 çalışabilmesi sayesinde sistemin zaman ve mekan gözetmeksizin kullanılabilir olmasını sağlamaktadır. İnternetin yaygınlaşması ve maliyetinin düşmesi iş modellerinin de buna paralel değişmesini sağlamıştır. İşletmenin satış-pazarlama, servis, dağıtım ekibi gibi sahada olması gereken kullanıcıları sisteme rahatça erişip ihtiyacı olan bilgileri sağlayabilmeli, kendilerine atanmış görevleri alabilmelidir. Yeni iş modellerinde çalışanlar gerekmedikçe ofiste durmayıp, sahada daha aktif olup müşterilerine daha çok zaman ayırabiliyorlar. İnternet, çalışanlarınızın mobil olmasını sağlamasının yanı sıra, müşterilerinizin veya potansiyel müşterilerinizin de size her an ulaşabilmesini sağlamaktadır. Sentez LiveERP, dünyanın her yerinden ve her zaman size ulaşmak isteyen çalışanlarınıza, müşterilerinize veya tedarikçilerinize bu olanağı sağlayan bir çözümdür.

Entegre Yapı

Sentez LiveERP iş çözümleri platformu, işletmeler için gerekli olan bütün modülleri içeren entegre bir platformdur. Geleneksel ticari iş çözümlerinde sunulan modüller sadece evrakları sisteme kaydetmek ve sonrasında raporlamak üzerine kurulmuştur. Günümüzde sadece bu kadarı yeterli gelmemekte, sistemin akıllı olması, her seviyedeki karar verme sürecini desteklemesi beklenmektedir. Geleneksel ticari uygulamaların kapsamı dışında tutulan Müşteri İlişkileri Yönetimi ve İş Zekası gibi modüller ayrıca satın alınıp, mevcut sisteme entegre edilmeye çalışılmıştır. Kimi zaman iki, kimi zaman daha fazla sayıdaki farklı çözümden oluşan sistemler, veri girişlerinin birçok kez tekrarlanmasından, çözümler arasındaki veri alış verişinin yeterince sağlıklı ve hızlı olamayışından kaynaklanan nedenlerden dolayı, beklenen performansı sağlayamazlar. Sentez LiveERP, iş süreçlerinin hemen hemen hepsinde müşteri ilişkileri yönetimi ve iş zekası modülleriyle bir bütün olarak tasarlanmış bir çözümdür.

Teknoloji

Ar-Ge faaliyetleri TÜBİTAK tarafından onaylanmıştır. Microsoft.Net Framework 4.0 platformu üzerine kurulmuş, C# ve ASP.NET dilleri ile geliştirilmiştir. Mimari tasarımında günümüzün modern yazılım modelleri olarak kabul edilen MVP / MVVM kullanılmıştır. Microsoft SQL Server, Oracle gibi endüstri standartı ilişkisel veritabanları (RDBMS) ile uyumlu, performans, veri güvenliği ve tutarlılığı ön planda tutularak tasarlanmıştır. Gerekli kaliteyi ve çevikliği sağlayabilmek için amacıyla “Ekstrem Programlama” yöntemleri uygulanmaktadır.

Güvenlik

Güvenlik sistemi ile kullanıcı bazında her işleme yetkilendirme yapılabilmektedir. Kullanıcıların hangi zaman diliminde ve hangi bilgisayardan veya hangi IP aralığından sisteme girebilecekleri belirlenebilmektedir. LOG sistemi ile kullanıcıların yaptığı her işlem, girdiği veya değiştirdiği kayıtlar veya aldığı raporlar anında takip edilebilmektedir.

Esneklik

Masaüstü kullanıcı arayüzleri MS Windows Presentation Foundation (WPF) teknolojisi kullanılarak hazırlanmıştır. Dinamik veri tabanı alan tanımlamaları sayesinde işletmenin veri tanımlamaları bazında gereksinim duyduğu bütün özelleştirmeler yapılabilir. %100 Microsoft .Net uyumlu script dili desteği sayesinde işletmeye özel kurallar belirlenebilir, özel işlemler yaptırılabilir. Raporlar ve formlar yazıcıya ve ekrana alınabildiği gibi, MS Excel, MS Word, MS PowerPoint, Adobe pdf, Open Office dosyası olarak veya metin dosyası, xml veya html formatında alınabilir, arşivlenebilir veya e-posta olarak gönderilebilir. Kişiye ve işletmeye özel sonsuz sayıda rapor ve form tasarımı yapılabilir.

Verimlilik

İş süreçleri modülü (BPM) sayesinde tanımlanan görevler, servisler, raporlar veya analizlerin belirlenen zamanlarda otomatik olarak çalışması ve çıktılarının istenilen ortamda hazırlanması sağlanabilir. Uyarı sistemi sayesinde işletmenin çalışma sistemi doğrultusunda gerekli kontroller tanımlanabilir ve istenilen kullanıcıların uyarılması sağlanabilir. Kullanıcı dostu çalışma listeleri sayesinde işlemlerin daha hızlı, daha pratik ve daha güvenli gerçekleştirilmesi sağlanabilir. İş zekası modülü sayesinde işletme bütünüyle karar verme sürecinin kapsamına alınmış olmaktadır. Erişilebilirlik Web ara birimi sayesinde dünyanın herhangi bir yerinden, herhangi bir zamanda, herhangi bir işletim sistemi ile firmanızın veri tabanına online erişerek, durumu her an izleyebilirsiniz. Web servisleri sayesinde 3.parti yazılımlar ile sorunsuz entegrasyon sağlanabilir. Mobil el terminalleri için hazırlanan uygulamalar kullanılarak işlemlerinizi yapabilirsiniz. İşin özelliklerine göre on-line veya off-line çalışabilen uygulamalar sayesinde depo çözümleri, mobil sıcak satış çözümleri veya lojistik çözümleri oluşturulabilmektedir.

Pazarlama ve Satış

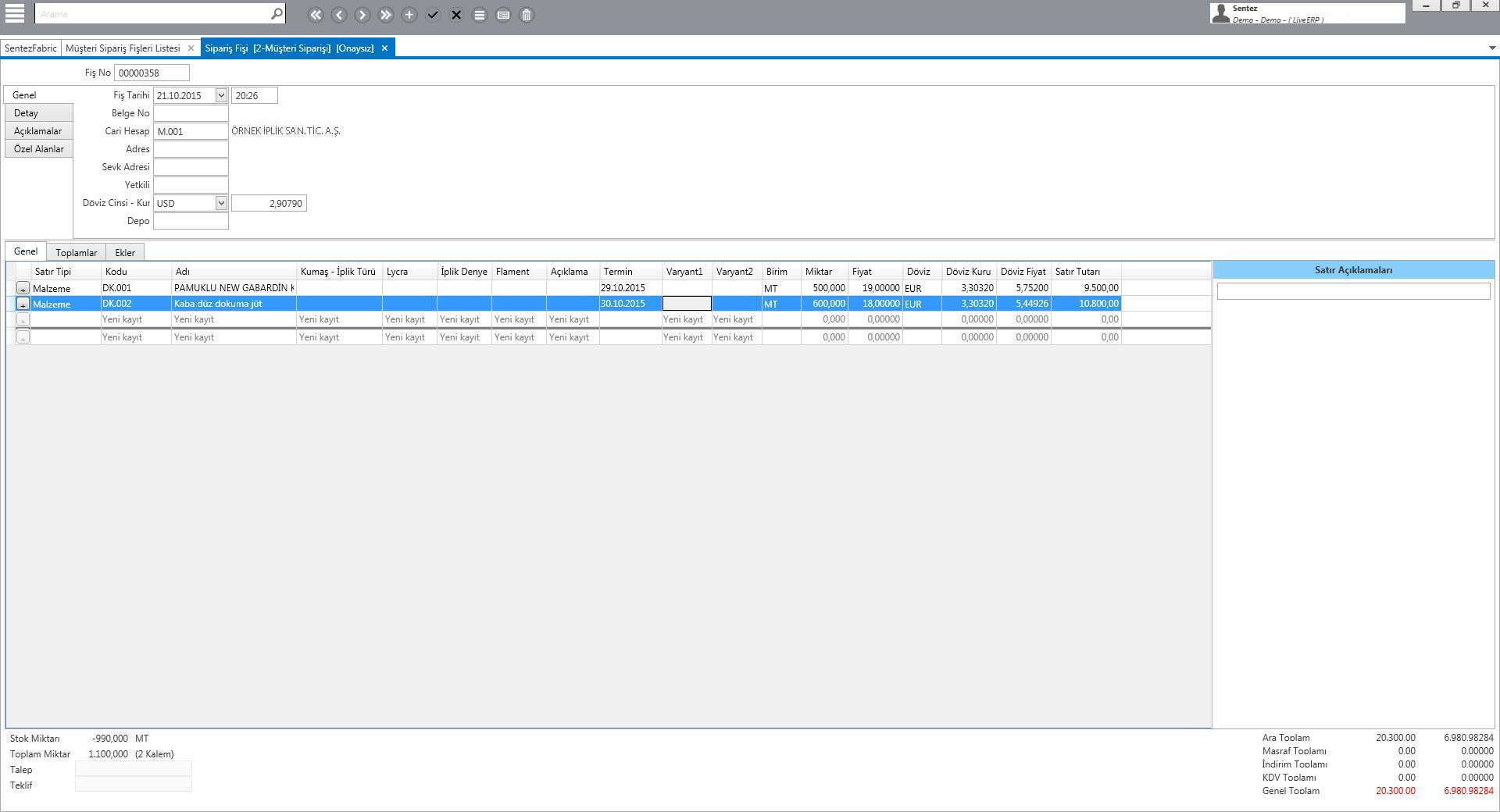

SentezLIVE DYE ile müşterileriniz, siparişlerinin durumunu internet üzerinden takip edebilirler. Müşteri sipariş bilgilerini detaylı olarak girebilirsiniz. Müşteriye ait talimat bilgilerini detaylı bir biçimde tanımlayabilirsiniz.Müşteri sipariş girişlerinde, renk kodlarını ve üretim prosesini belirtebilirsiniz. Siparişin işletmedeki üretim durumunu (partileşen, boyanan, sevk olunan şeklinde) takip edebilirsiniz. Sipariş formunu istenilen şekilde dizayn edebilir, sipariş formunun müşteri okeyi için direkt olarak faks çekebilirsiniz.Müşteri siparişlerini otomatik olarak iş emrine aktarabilirsiniz. Boya, kimyasal madde, yedek parça ve diğer işlemlerin takibini yapabilir, müşteri ve stok bazında detaylı raporlar alabilirsiniz.

İş emri oluşturulmamış siparişleriniz için iş emri numarası ataması yapabilirsiniz. Sınırsız sayıda sipariş analiz küpü (OLAP) oluşturabilir bu sayede siparişlerinize ait detaylı istatistikler alabilirsiniz.

Laboratuvar

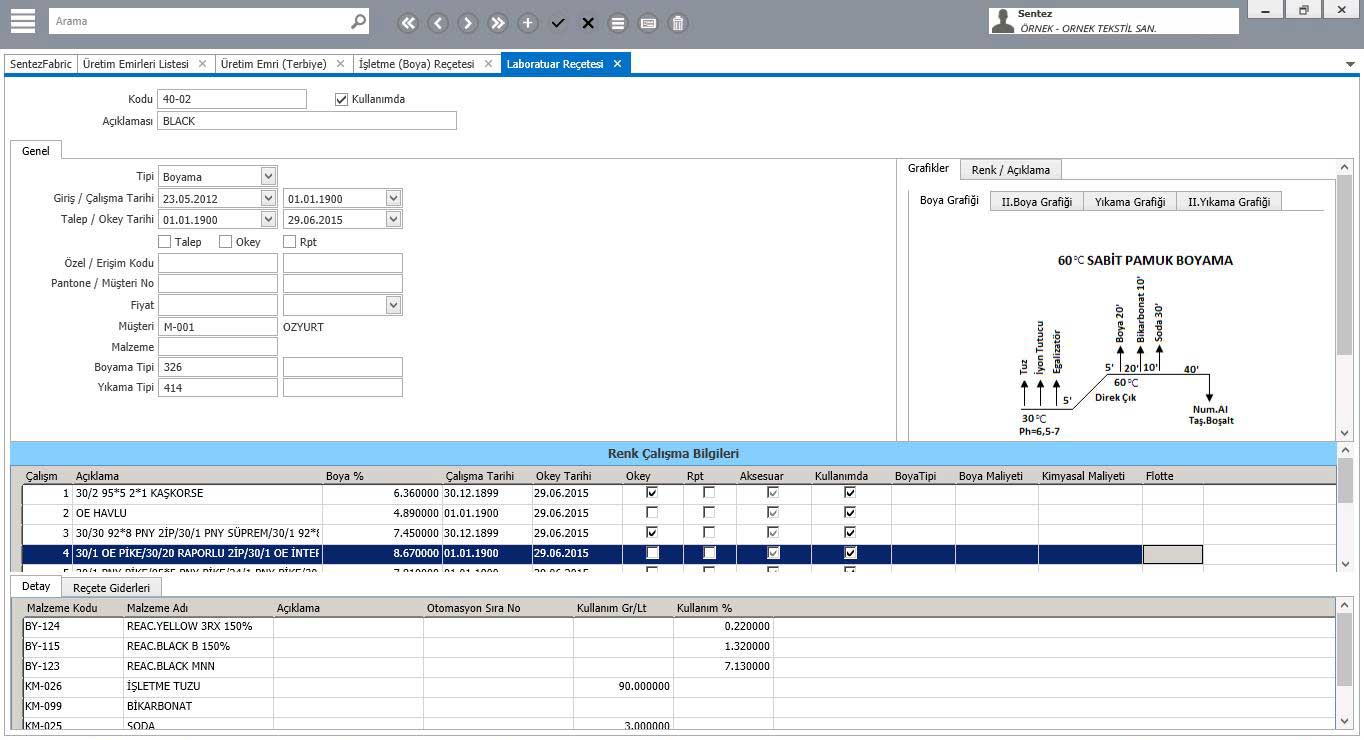

SentezLIVE DYE ile sınırsız sayıda renk çalışmaları yapabilir, aynı renk için ilave reçeteler hazırlayabilirsiniz. Müşteri ham kumaş ve renk bazında detaylı reçete listesi alabilirsiniz. Müşteri ve ham kumaş bazında reçete tanımlayabilirsiniz. Renk reçetesi ile ilgili detaylı açıklamalar tanımlayabilirsiniz.Kullanılan hammaddeler doğrultusunda boya yüzdesini ve boya maliyetini hesaplayabilirsiniz. Boya ve yıkama prosesine göre grafikler hazırlayabilirsiniz. Renk bazında birim boya maliyetini otomatik hesaplatabilir, genel giderleri boya maliyetlerine yansıtabilirsiniz.Anlaşmadaki fiyatları, siparişe veya sevk irsaliyesine otomatik olarak getirebilirsiniz. Renk maliyet formunda kâr analizi yapabilir, renk maliyetini üç farklı döviz cinsine göre hesaplatabilirsiniz. Renk, işlem ve reçete bazında fiyat anlaşmaları yapabilirsiniz.

Müşteri bazında laboratuvar çalışmalarına ait istatistik alabilirsiniz. Okeylenen ve okeylenmeyen renkleri müşteri bazında raporlayarak takip edebilirsiniz. Parametrelerde tanımladığınız reçete genel gider kalemlerini laboratuvar reçetesi içerisine otomatik olarak aktarabilirsiniz.Renk maliyet formu üzerinde hesaplanan maliyet bilgilerini otomatik olarak renk maliyet tarihçesine aktarabilir renge ait maliyet çalışmalarının tarihçesini oluşturabilirsiniz. Renk maliyet formu üzerinden verilen fiyat bilgilerini müşteri/renk fiyat anlaşmalarına otomatik olarak aktarabilirsiniz.

İş Emri Takibi (Parti Kartı)

İş emri (Parti kartı) bilgilerini detaylı olarak tanımlayabilirsiniz. Müşteri siparişlerinden otomatik iş emri hazırlayabilirsiniz. Barkodlu ve barkodsuz iş emri dökümü alabilirsiniz.İş emri üzerinde işletmeye özel alanlar tanımlayabilirsiniz. İşletmeye uygun birden fazla parti refakat kartı dizaynı yapabilirsiniz. Sınırsız iş akış prosesi tanımlayabilirsiniz. İş emri kartı üzerinde ürün bazında iş akışı tanımlayabilirsiniz.

Tamir partileri (iç+dış) takip edebilirsiniz. Boya işleminde kullanılacak kimyasalların otomatik takibini yapabilirsiniz. Partiye ait hammadde sarfiyatına tek bir tuş ile ulaşabilirsiniz.

Üretimin herhangi bir aşamasında partiyi, alt partilerine bölebilir, aynı boya kazanına girecek tüm partileri birleştirebilirsiniz. Partilere ait tüm hareketleri tek bir form üzerinde takip edebilirsiniz. Flote miktarını otomatik hesaplatabilirsiniz.

Master iş emri üzerinden iş emri kopyalayabilirsiniz. Ham kumaş girişleri doğrultusunda otomatik tahsis işlemi yapabilirsiniz. İş emri üzerinden otomatik planlama oluşturabilirsiniz. Terazi bağlantısı ile parti miktarını terazi üzerinden alabilirsiniz.

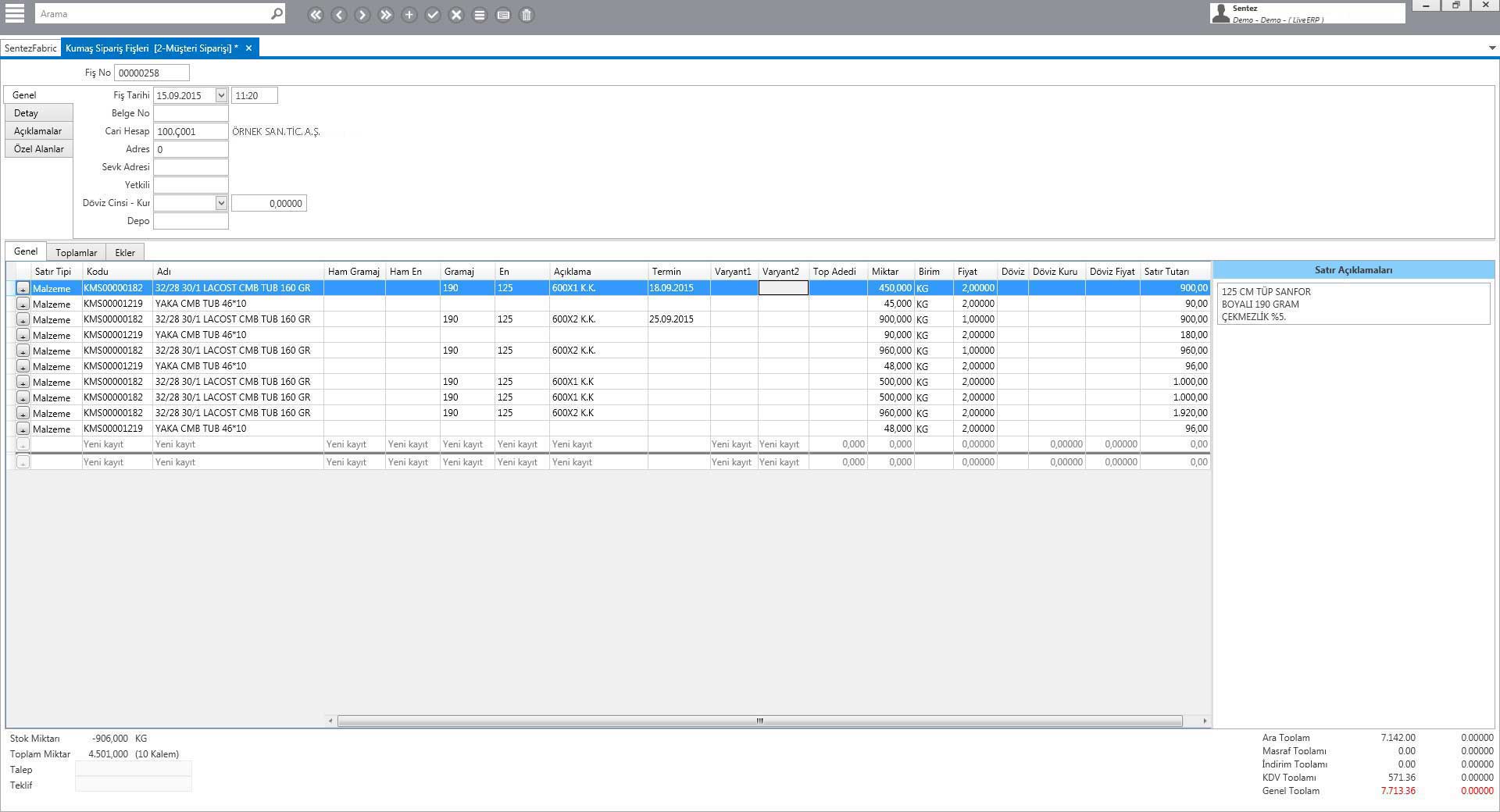

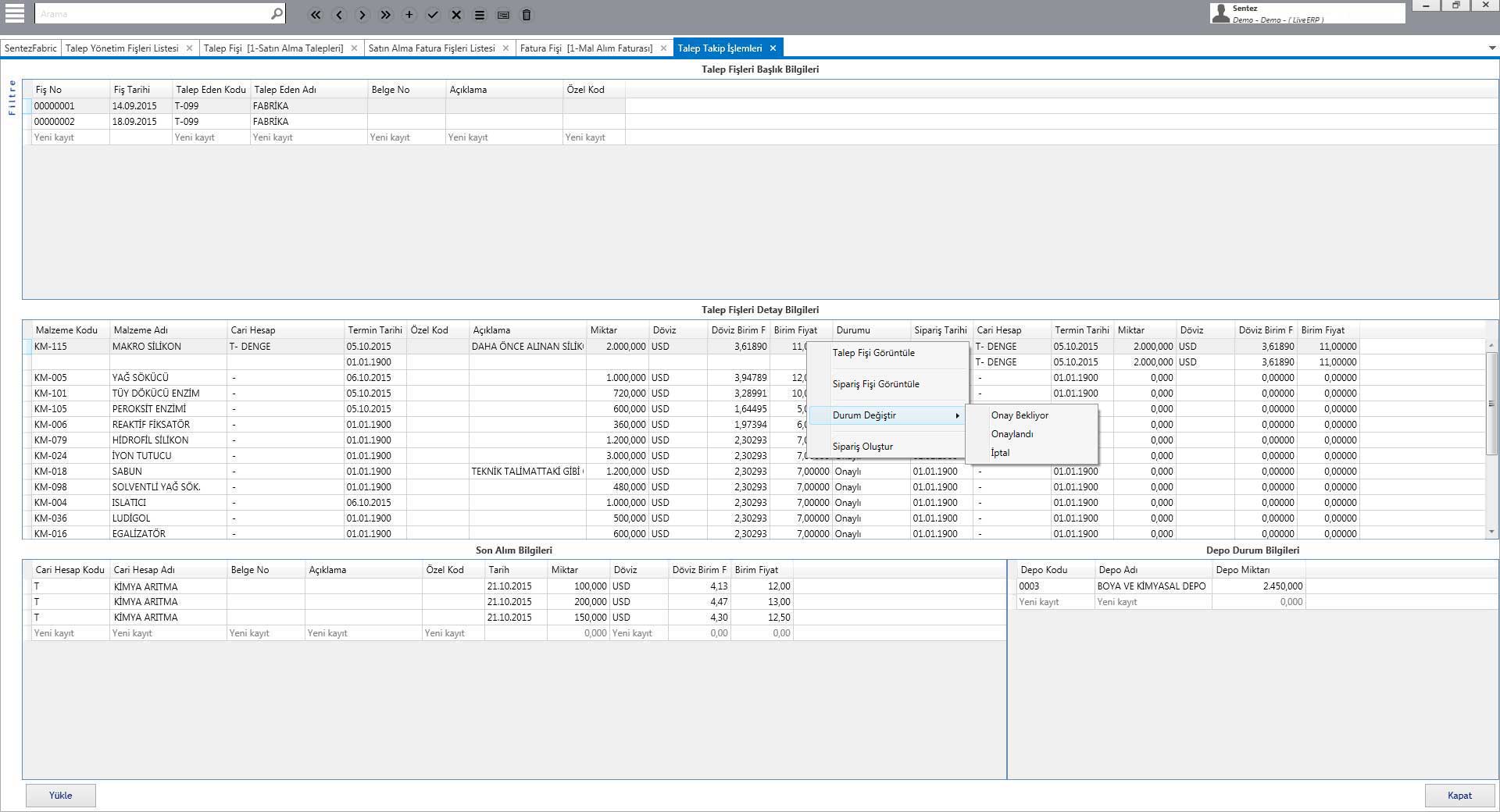

Satın Alma Yönetimi

SentezLIVE DYE programının satın alma yönetimi modülü sayesinde, satın alma sipariş bilgilerini detaylı olarak girebilirsiniz.Satın alma siparişini otomatik olarak irsaliye üzerine aktarabilirsiniz. Stok bazında kritik stok miktarı tanımlayabilir ve kritik stok miktarı altındaki stoklarınıza tek bir ekran üzerinden ulaşarak otomatik sipariş verebilirsiniz.Açık-kapalı sipariş dağılımını, stok ve cari hesaplar bazında takip edebilirsiniz. Tedarikçi ve stok bazında detaylı raporlar alabilirsiniz.

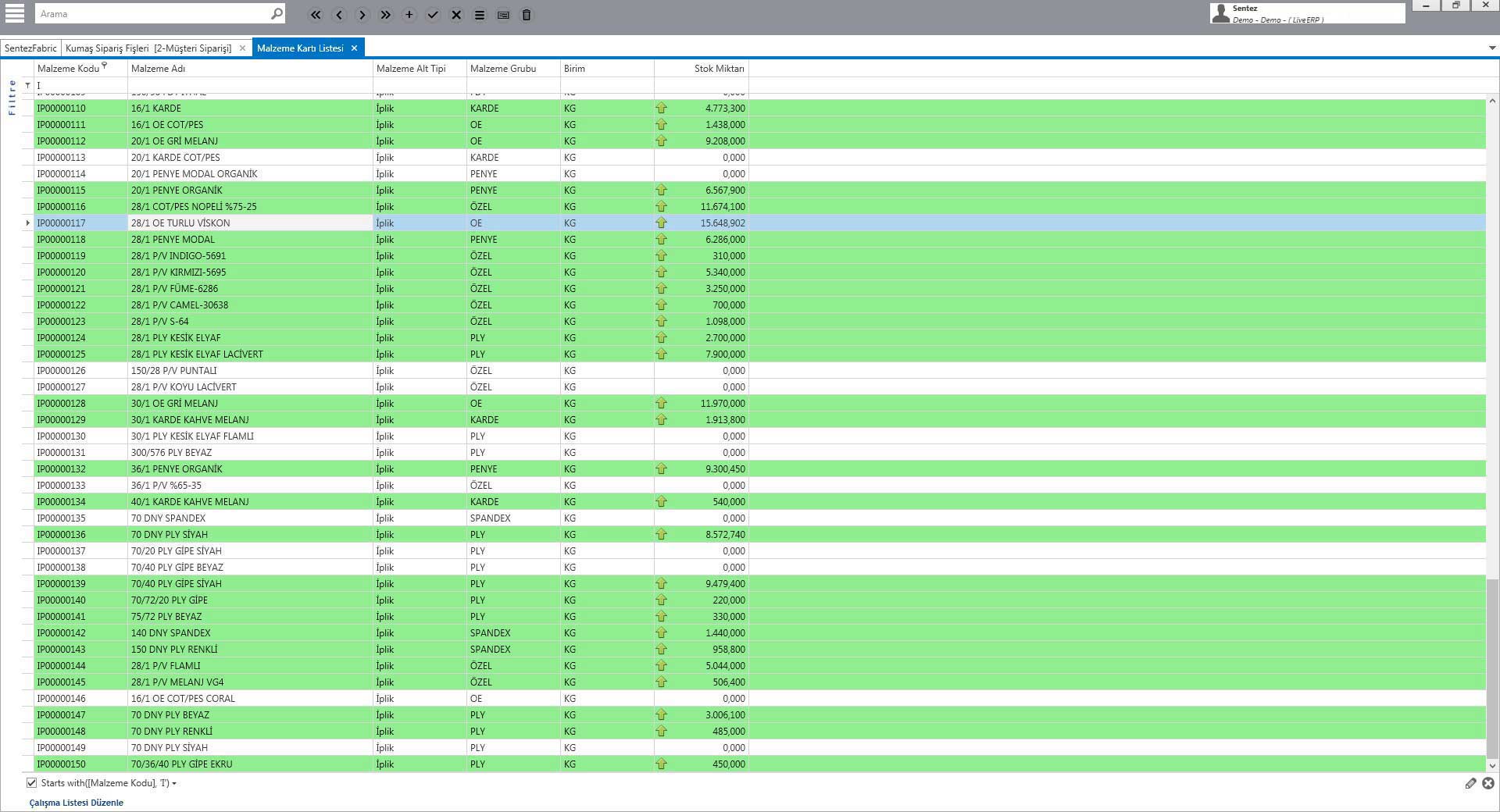

Depo Yönetimi

SentezLIVE DYE programının parametrik yapısı sayesinde stoklarınızı detaylı bir şekilde tanımlayabilirsiniz. Müşterilerinizin ham kumaş ve iplik stoklarını depo bazında takip edebilirsiniz. İş emri (parti kartı) hazırlarken depodaki stoklarla tahsis yaparak ilişkilendirebilirsiniz. Depo bazında iade işlemlerinizi takip edebilirsiniz.Stokları üretim işlemleri ile ilişkilendirebilirsiniz. Stoklara ait hareketleri detaylı olarak takip edebilirsiniz. Boya ve kimyasalların depo girişlerini gerçekleştirebilirsiniz.Boyama ve diğer operasyonlarda kullanılan boya ve kimyasalların otomatik düşümünü yapabilirsiniz. Boya ve kimyasalların hangi operasyonlarda (ön işlem, kasar, boyama, yıkama vb.) kullanıldığını raporlayabilirsiniz.

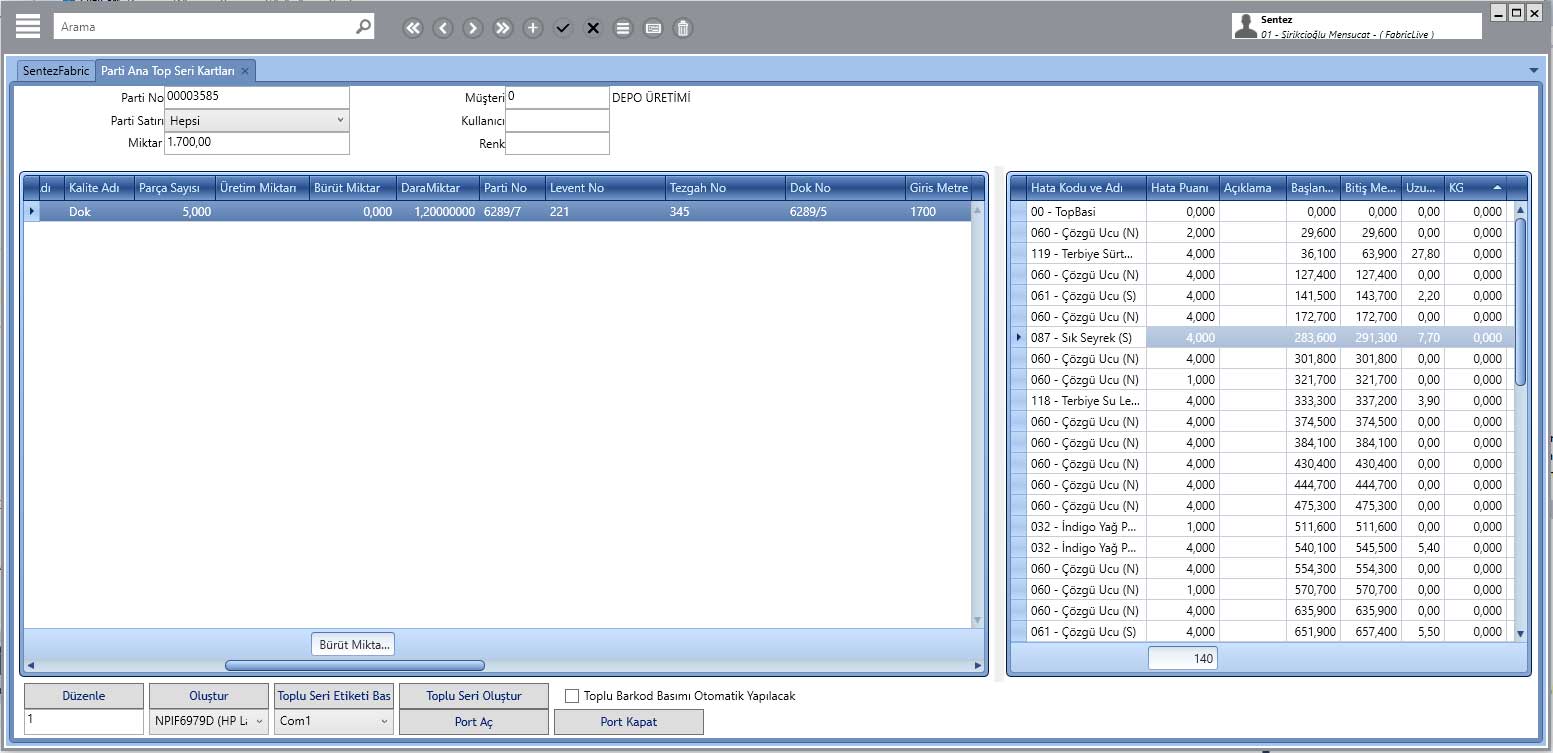

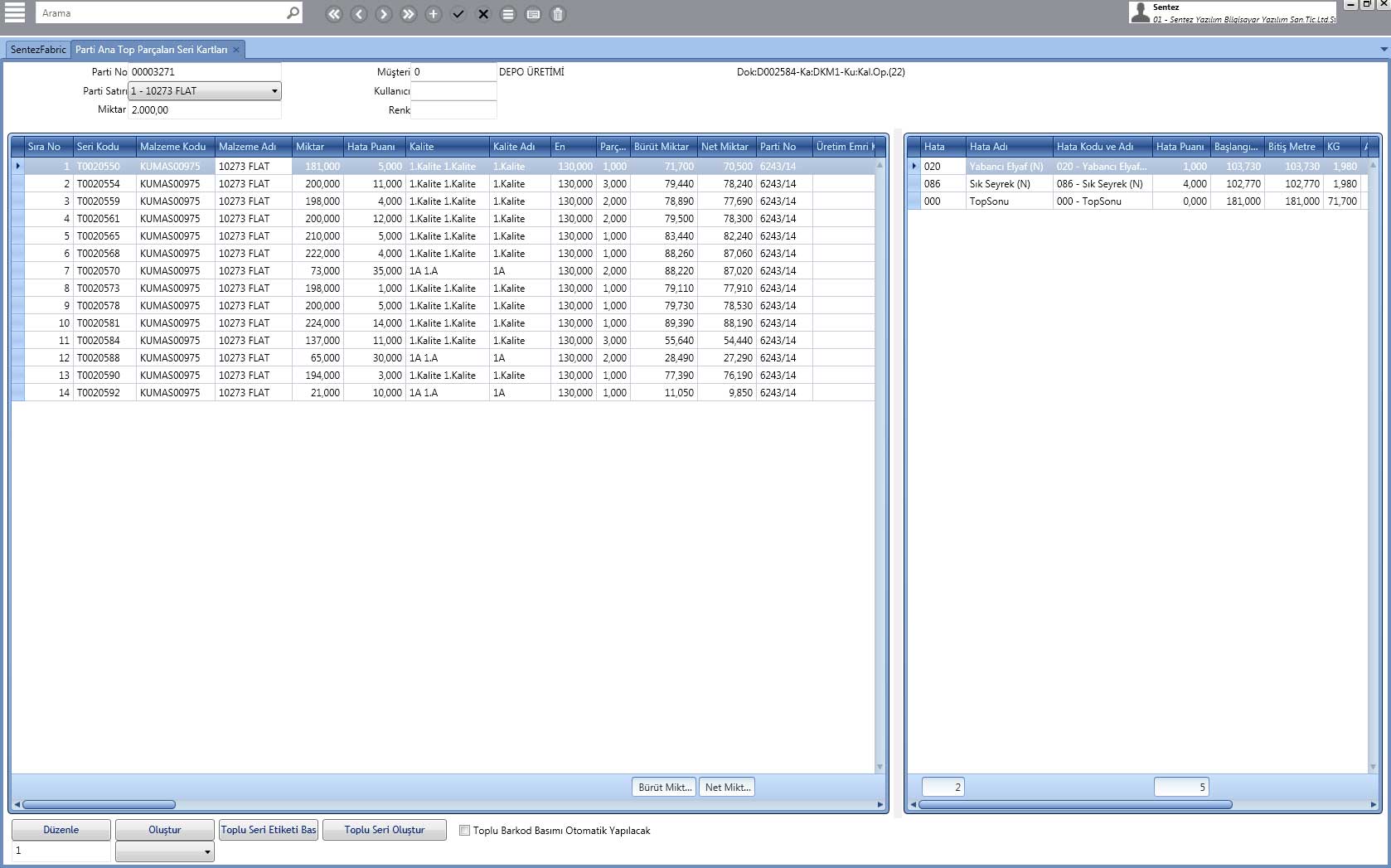

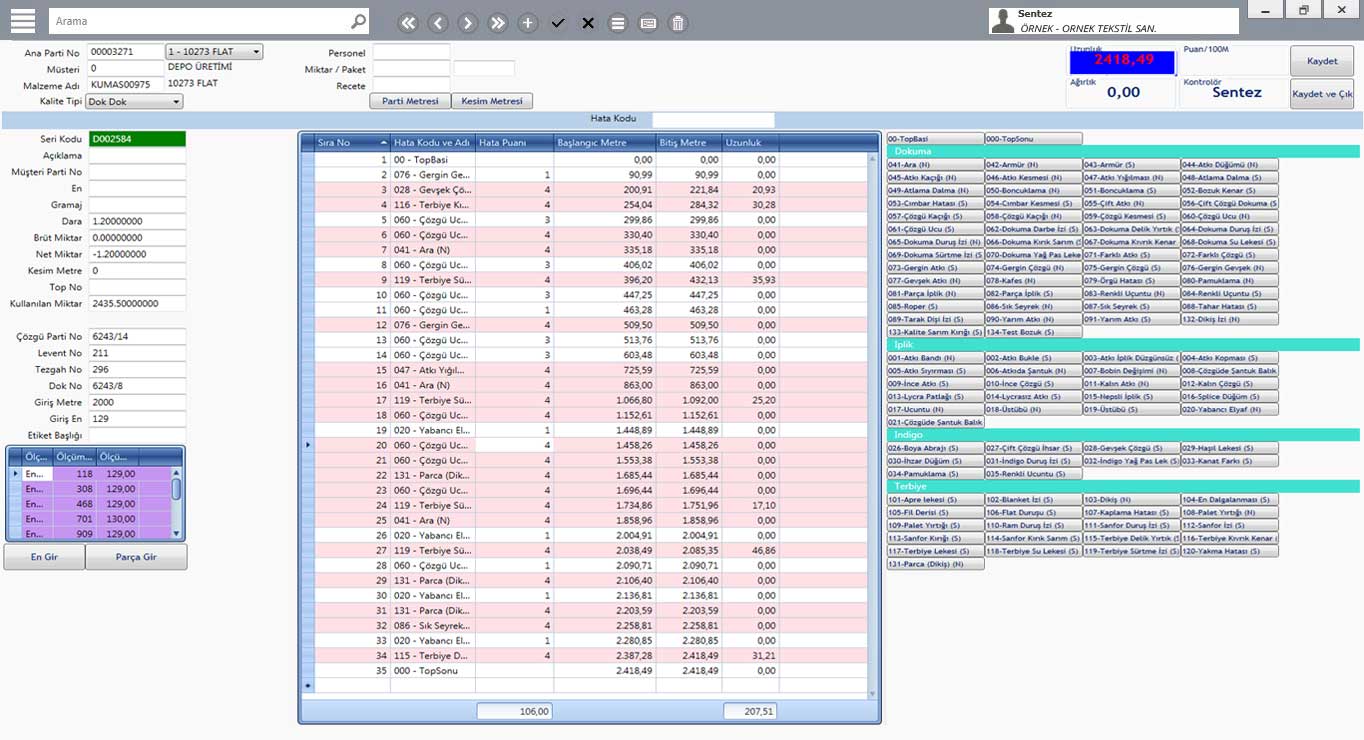

Seri (Top) Takibi

Parti Kartı üzerinden otomatik seri (top) kartı üretebilirsiniz.Sınırsız hata tipi kartları tanımlayabilirsiniz. Hata puanlarını kart üzerinde belirleyebilirsiniz.Detaylı seri (top) kartı tanımlayabilirsiniz. Seri (top) kartı üzerinde hataları ve bu hataların başlangıç metresi ve uzunluklarını tanımlayabilirsiniz. Seri (top) kartının toplam hata puanına göre kumaş kalitesini belirleyebilirsiniz. Seri (top) kartına ait hataları içeren barkodlu döküm alabilirsiniz.Tanımlanan seri (top) kartlarını sevk irsaliyesine aktarabilirsiniz. Barkodlu ürün etiketi hazırlayabilirsiniz.

Seri (top) bölme ve birleştirme işlemlerini yapabilirsiniz. Kalite kontrolü yapılan/yapılmayan seriler (top) ile ilgili raporlar alabilirsiniz.

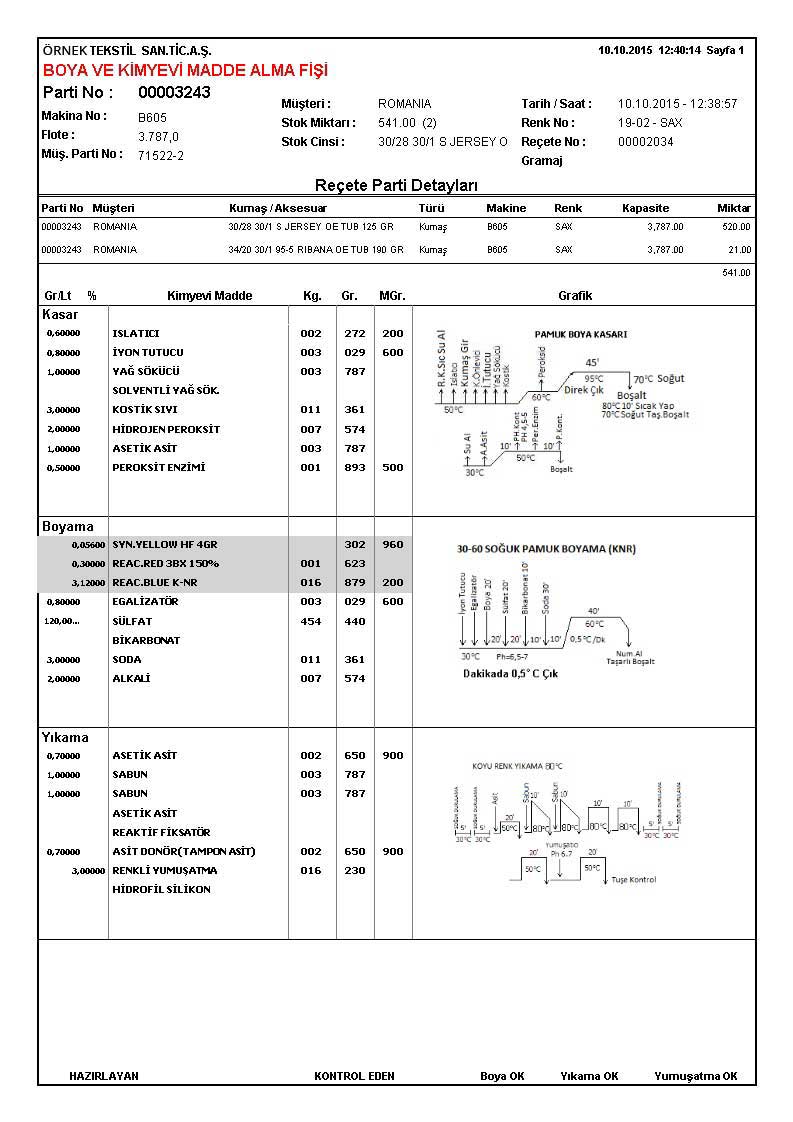

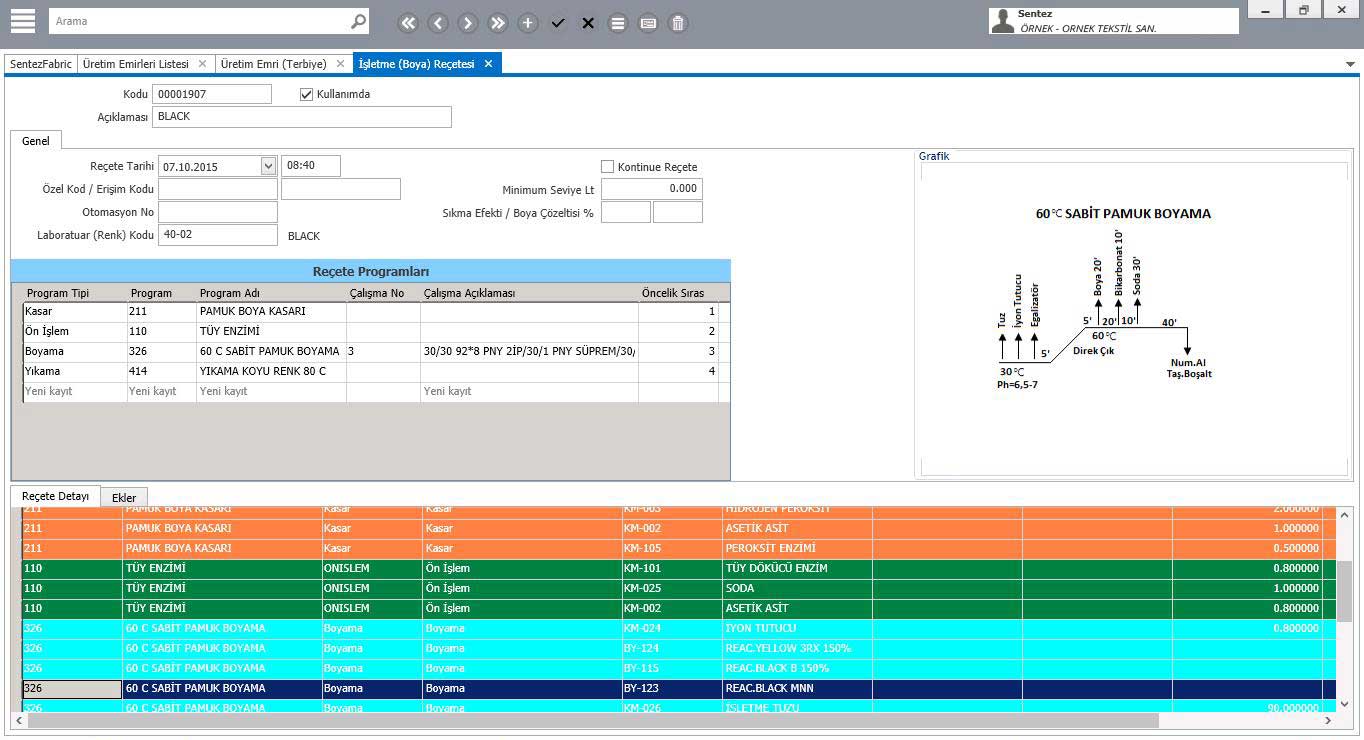

Reçete (İşletme Reçetesi)

SentezLIVE DYE ile sınırsız reçete tanımlayabilirsiniz. Parametrik yapısı sayesinde farklı boyama yöntemlerine (Overflow, pad-batch vb.) göre reçete oluşturabilirsiniz.Ön işlem, kasar, boyama, yıkama ve yumuşatma tipi belirleyerek reçete üzerine kimyasal madde ve oranları otomatik getirebilirsiniz. Reçete ile ilgili detaylı açıklamalar tanımlayabilirsiniz. Reçete ön değer tanımlarından alınan bilgiler doğrultusunda otomatik reçete oluşturabilirsiniz.Laboratuvar çalışmalarını otomatik olarak reçete üzerine aktarabilirsiniz. Çift boya reçeteleri (pamuk, polyester, naylon v.b. gibi) hazırlayabilirsiniz. Baskı reçetesi hazırlayabilirsiniz. Sınırsız sayıda ilave ve tamir reçetesi hazırlayabilirsiniz.İşlemlere ait grafikleri otomatik olarak reçete üzerine getirebilirsiniz. Otomatik düzenlenen reçete üzerinde kimyasal ve grafik değiştirebilirsiniz. Reçete dökümü alabilirsiniz. Master reçete üzerinden reçete kopyalayabilirsiniz.

Üretim Planlama

SentezLIVE DYE tekstil programı ile iş emirlerinin (partilerin) hangi kazanda boyanacağını planlayabilirsiniz. Tüm partileri tek bir ekranda izleyebilirsiniz. İşletmeye üretim talimat programı hazırlayabilirsiniz. Bugüne kadar açılan tüm partilerin kartlarına erişebilir ve önceki tarihlerdeki parti durumlarını görebilirsiniz.Tek bir tablo üzerinde saat bazında makine ve kazan planlaması yapabilir, işletmenin 24 saat üretim durumunu görebilirsiniz. Partilerin tüm üretim aşamalarını detaylı olarak izleyebilirsiniz. Partilere ait planlama kayıtlarını işlem makina grupları bazında otomatik olarak gerçekleştirebilirsiniz.

İşletme durumu ekranında işletmenizin şu anki durumunu takip edebilirsiniz. Makine grupları oluşturarak (boya, apre vb.) planlama ve üretim formları üzerinde ayrı olarak takip edebilirsiniz. Standart zamanları detaylı (işlem, makine, ürün grubu vb.) olarak işleyebilirsiniz.

Planlama listesi sayesinde işlemlere ait toplu planlamalar gerçekleştirebilirsiniz. Planlama esnasında makine kapasite kontrolü yapabilirsiniz. Çakışan planlama kayıtları için zaman bilgisinin otomatik olarak düzenlenmesini sağlayabilirsiniz. İşlem makine grupları oluşturarak işlemlerin yanlış makinelere planlanmasını engelleyebilirsiniz.

Partinin route harici işlemlere planlanmasını engelleyebilirsiniz. Planlaması yapılıp üretimi başlamamış partilerin raporlarını alabilirsiniz. Planlama ve üretim bilgilerini karşılaştıran raporlar alabilirsiniz.

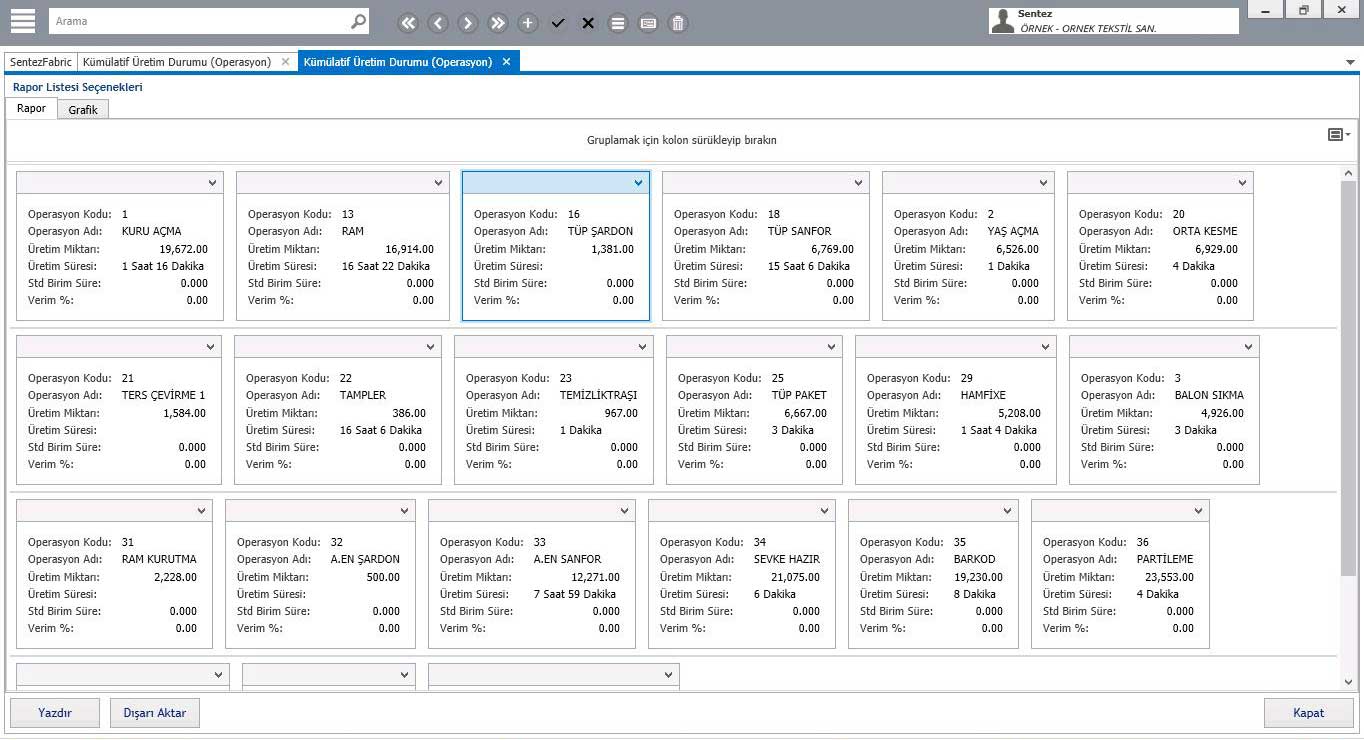

Üretim Takibi

SentezLIVE DYE üretim takibi modülü ile üretimin gerçekleşme tarih ve saatlerini görebilirsiniz. Her bir operasyonda, üretim detaylarını takip edebilirsiniz. Üretimi gerçekleştiren personelin verimliliğini ölçebilirsiniz. Genel ve detaylı üretim raporları alabilirsiniz.Üretimin başlangıç ve bitiş işlemlerini barkod okutarak sisteme transfer edebilirsiniz. İşlem yapılan operasyonda iken, önceki operasyonları izleyebilirsiniz. Partiye ait üretim tarihçesini takip edebilirsiniz. Üretimin diğer bölümlerden, anlık olarak izlenmesini sağlayabilirsiniz.

Gerçekleşen çıkış eni, gramaj gibi üretim sonrası bilgileri takip edebilirsiniz. Parametrik yapısı sayesinde üretime ait detay bilgiler takip edebilirsiniz. Makinelere ait kayıp zaman ve duruş bilgilerini detaylı olarak takip edebilirsiniz. Route kontrolü sayesinde hatalı üretim hareketlerinin oluşmasını engelleyebilir ve üretimin sağlıklı yürümesini sağlayabilirsiniz.

Özel barkod yapıları oluşturarak partiye ait ek işlemlerin üretim bilgilerini route kartına müdahale etmeden gerçekleştirebilirsiniz. Grup partilerin üretim bilgilerini ayrı ayrı veya birlikte takip edebilirsiniz. Son işlemden çıkmayan partinin sevkiyatını engelleyebilirsiniz.

Partilerin şu anki üretim durumları ve daha sonraki üretim aşamalarını raporlayabilirsiniz. Üretim esnasında barkodlu/barkodsuz detaylı formlar basabilir bu form üzerine iş emri ve üretime ait detaylı bilgilerin çıkmasını sağlayabilirsiniz. Sınırsız sayıda üretim analiz küpü (OLAP) oluşturabilir bu sayede üretime ait detaylı istatistikler alabilirsiniz.

Kalite Kontrol Yönetimi

SentezLIVE DYE programının Kalite Kontrol Yönetimi modülü ile partideki ürünlere ait kalite kontrol bilgilerini detaylı olarak girebilirsiniz.İş Emri (Parti Kartı) satırından tek bir tuş ile kalite kontrol bilgileri formuna ulaşabilirsiniz.Kalite değerleri uygun olmayan ürünlerin sevkiyatını engelleyebilirsiniz. İşlem bazında kalite kontrol değerlerini detaylı olarak takip edebilirsiniz. Kalite kontrol test kartları oluşturabilirsiniz.Partiye ait test bilgilerini işlem bazından detaylı olarak (metot, standart vb.) işleyebilirsiniz.

Kalite kontrol test rapor dökümlerini alabilirsiniz. İşletmeye özel kalite kontrol formları dizayn edebilirsiniz. Ürünlere ait kalite kontrol formu dökümü alabilirsiniz.

Sevkiyat

LIVEDYE ile müşteri sevkiyatlarınızı parti veya sipariş bazında gerçekleştirebilirsiniz. Hangi partilerin müşteriye sevk edileceğini seçip sevkiyat planlaması yapabilirsiniz. Sevkiyat planlama raporunu alarak, depoya talimat verebilirsiniz. Sevk olmayan partileri, termin tarihine göre listeleyebilirsiniz.Üretimi biten partilerin sevkiyat irsaliyesini oluşturabilirsiniz. Sevkiyatı gerçekleştirilen partiye uygulanan işlemleri takip edebilirsiniz. Kısmi sevkiyat yapabilirsiniz. Barkodlu sevkiyat yapabilirsiniz.

Üretimi tamamlanmayan, kalite kontrol onayı verilmeyen partilerin sevkiyatını engelleyebilirsiniz. Partinin tüm kalemlerinin birlikte sevk olmasını sağlayabilirsiniz. Partilerin net miktarlarını yazarak firelerinin otomatik hesaplanmasını sağlayabilirsiniz.

Terazi bağlantısı ile sevk miktar bilgilerini terazi üzerinden otomatik olarak sevk fişine aktarabilirsiniz. Sevkiyat fişi üzerinde birim fiyat hesaplatması yapabilirsiniz. İrsaliye üzerinde iş emri bilgilerini tanımlayabilirsiniz.

Fatura bağlantısı yapabilirsiniz. İstenilen bazda (tarih, müşteri vb.) sevkiyat raporları alabilirsiniz.

Faturalama

Tekstil programının faturalama modülü ile sevk irsaliyeleri doğrultusunda, otomatik olarak irsaliyeden fatura işlemi yapabilir, aynı fatura üzerinde birden fazla irsaliyeyi faturalaştırabilirsiniz.Faturayı partiye uygulanan işlemler doğrultusunda (sizin belirleyebileceğiniz) oluşturabilirsiniz. Fatura tutarlarının işlem bazında net miktar veya brüt miktar üzerinden hesaplanmasını sağlayabilirsiniz. Faturalaştırılmamış irsaliyeleri takip edebilirsiniz.

Girişi yapılan faturalar isteğe bağlı olarak diğer modüllere entegre edilebilir.

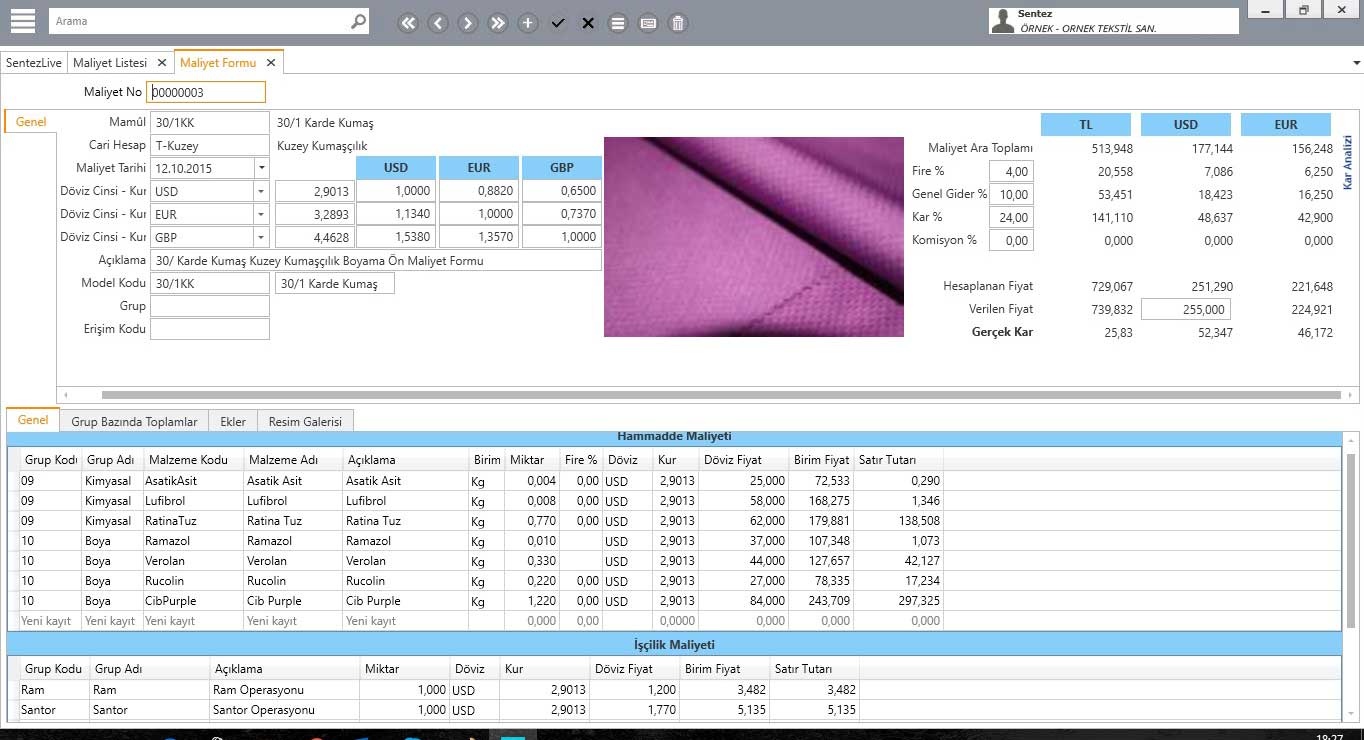

Maliyet

Gerçek maliyeti otomatik olarak hesaplayabilirsiniz.Tahsisler ve hammadde sarfiyatı sayesinde parti/sipariş maliyetini otomatik olarak alabilirsiniz.Gelir-gider ve kâr-zarar analizleri yapabilirsiniz. Reçete maliyetlerinde kâr analizi yapabilirsiniz.Proforma maliyet ve gerçek maliyet tablosunu parti bazında karşılaştırmalı olarak alabilirsiniz. Grup partilerin maliyetini ayrı ayrı veya birlikte takip edebilirsiniz. Döviz ve Türk Lirası bazında maliyet raporları alabilirsiniz.

SentezLIVE DYE ile Finans Yöneticileri, geleceği öngörmede ve geçmişi değerlendirmede, yatırımlarla veya finansmanla tüm finansal kararların alınmasında rasyonelliği yakalayabilmek ve doğru karar verebilmek için ihtiyaç duyacakları veri analizlerine kolaylıkla ulaşabilmektedirler.

Aynı zamanda işletmenin finansal analizinin yapılması, işletmenin faaliyet sonuçlarının değerlendirilmesi, planlar yapılabilmesi ve kaynakların doğru alanlara yönlendirilebilmesi açısından gerekli tüm verileri SentezLIVE DYE Finans Yönetimi size sunar.

Finansal veriler, sadece yönetimin finansal kararları almasında değil, aynı zamanda pazarlama, üretim, insan kaynakları, ar-ge ve işletmeyle ilgili tüm stratejik kararların alınmasında etkili verilerdir.

İşletmede karlılığı artırmak için alınan kararlar beraberinde riski de artırmaktadır, etkin ve başarılı finansman yönetimi, özellikle kısa süreli yatırım kararlarının alınmasında önemli ve büyük rol oynar.

Tanımlanabilen ve özelleştirilebilen risk hesaplama yöntemleri sayesinde değişen piyasa koşullarına karşı işletmenizin adapte olmasını sağlar.İşlemlerinizi farklı dövizler kullanarak yapabilmenizi sağlar. Yerel para birimi veya döviz olarak girilen tutarların otomatik olarak işlem dövizi cinsinden hesaplanmasını sağlar.

Cari hesaplarının farklı dövizlerden bakiyelerini takip edebilmenizi sağlar.Raporlamalar için farklı döviz belirleyebilmenizi sağlar. Yerel para birimi veya döviz olarak girilen tutarların otomatik olarak işlem dövizi cinsinden raporlanmasını sağlar.

Ödeme-tahsilat planı baz alınarak yapılan ödeme ve tahsilatın vadelerine göre kontrol edilerek gerektiğinde vade farkı hesaplanmasını ve hesaplara yansıtılmasını sağlar.

Dövizli işlemlerinizde zaman içerisinde artı-eksi yönde değişen döviz kurlarının yerel para biriminize göre değişiminin otomatik olarak hesaplanmasını ve hesaplara yansıtılmasını sağlar.

İşletmeleriniz arasında işlem transferi servisleri sayesinde çapraz işlemlerinizi hatasız olarak oluşturmanızı sağlar. Bir işletmeniz için satış olarak kaydedilmiş bir evrağı diğer işletmeniz için alış olarak taşıyabilmenizi sağlar.

Teminat yönetimi sayesinde aldığınız veya verdiğiniz teminatları takip etmenizi ve dilediğinizde cari hesaplarınınız risklerini hesaplarken belirli oranlarda etkili olmasını sağlar.

SentezLIVE DYE İş Çözümleri Platformu, içerdiği tüm modülleriyle bir iş zekâsı sistemi olarak tasarlanmıştır.Her kullanıcının sistemdeki rolü doğrultusunda vermesi gereken kararları, doğru zamanda alabilmesi için gerekli bilgileri sağlar.

Bu bilgi akışı uygulamanın yapısına göre gösterge panelleri, analiz küpleri veya raporlar aracılığıyla sağlanmaktadır.

Temel Özellikler

Kolay erişim

Kolay kullanım

Esnek, güvenilir yapı

Desktop, mobil, internet/intranet üzerinde çalışma

Değişken görsel tasarım

Raporlar

Analizler

Kontrol Panel

Analiz Küpleri